Business Consulting Services

AusTech is a dynamic and forward-thinking consulting company specializing in Business Development and Innovation processes. Our mission is simple yet profound: to empower businesses to thrive in today's fiercely competitive market by delivering unparalleled customer value through cutting-edge industry insights and innovative engineered solutions.

In the industrial business landscape, innovation is the driving force behind success. To remain ahead of the curve, businesses must constantly evolve and adapt. This is where we step in. At AusTech, we collaborate with our clients to turn their aspirations into reality, guiding them towards their business goals through a combination of application insights, integrated technologies, strategic business development, and growth strategies.

Here's what sets us apart

Industry Expertise

Our deep-rooted industry knowledge spans across various sectors, with a particular focus on Metals (steel & aluminum), Mining, and Oil & Gas (both on land and offshore). We understand the unique challenges and opportunities that each of these sectors presents, allowing us to tailor our solutions to meet your specific needs.

Innovative Solutions

We offer Compliance Solutions that are designed to revolutionize the Offshore Oil & Gas industry. Our solutions aim to extend the mandatory critical asset inspections that often lead to costly vessel downtime. By optimizing inspection processes, we help our clients save millions in lost productivity while ensuring the highest safety and compliance standards.

Unlocking Ideation

Innovation starts with ideas, and we understand that evaluating, selecting, and pursuing the right ideas can be a daunting task. That's why we provide additional insights into the innovation development process, particularly in the realm of "IDEATION." We help you answer critical questions such as: How do you know which idea is the best idea? Who in your organization is responsible for evaluating your idea bank? What criteria should be used to judge the value of these ideas? We offer expert guidance and methodologies to streamline your innovation journey.

At AusTech, we are passionate about innovation, and we believe that it's not just about having great ideas; it's about bringing them to life. With our expertise, dedication, and commitment to excellence, we are ready to be your trusted partner on this exciting journey of growth and innovation.

Join us as we embark on a transformative journey that will redefine the way you do business. Together, we can shape the future of your industry, one innovative idea at a time.

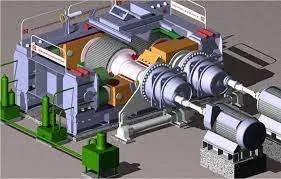

HELIX DriveLine

The Helix Driveline is the latest addition to the HELIX family of monitoring solutions, with applications in Steel, Mining, Oil and more.

Steel & Aluminum Production

Pinion Stand Gearboxes and Drive Motors are critical to the rolling mill operation with large gear sets and bearings. Typically, there are no replacement gearboxes kept as spares on-site due the their large dimensional foot print and cost. However, spare gear sets and bearings are typically maintained on site and installed in the event of unexpected gear or bearing failure. Undetected pinion stand failures result in significant production losses from the caster through to the hot & cold rolling mills. These are some of the areas that keep a mill superintendent awake at night. Helix Driveline may be the right solution to maintain productivity and peace of mind.

Mining & Mineral Processing Assets

Performance and Reliability are fundamental in the mining industry due to their direct impact on safety, productivity, cost-efficiency, environmental responsibility, equipment longevity, and the ability of mining companies to maintain a competitive advantage. Investing in high-quality, dependable equipment is essential for the success and sustainability of mining operations.

Mining operations involve significant upfront and ongoing costs. Unplanned maintenance, repairs, and replacement of unreliable equipment can lead to substantial budget overruns. Equipment with a track record of performance and reliability can help control operational costs and increase the return on investment. operations.

Whether you have ore trucks, horizontal or vertical grinding mills, conveyor drive systems, there is a Helix Driveline solution that can be tailored to your specific needs.

Offshore Oil & Gas

Offshore Drilling operators that desire to extend the mandatory Propulsion Thruster inspection interval require a Condition Monitoring system to be installed on their offshore drill ships that meets the requirements of the American Bureau of Shipping (ABS). A thruster monitoring program can extend the mandatory 5 year thruster inspection survey interval to a condition based inspection. Thruster remote monitoring and diagnostics is an essential component for offshore drilling operations to achieve this goal.

The Helix Driveline Thruster Monitoring package includes an online vibration measurement hardware platform with integrated oil condition monitoring to determine overall health of the thruster system. The system can analyze the thruster lubrication system for metallic wear debris, moisture content in oil and overall oil condition. The package is installed on each thruster, typically 6 per vessel.

Based on the real time thruster condition, ABS will grant the drilling operator an extension of the mandatory survey interval of 5 years to a condition based inspection requirement which provides approximately U$3 million in savings avoiding the risky operation of putting divers into the ocean.

Land Based Oil & Gas

One of the growing applications of screw compressors today is gas well treatment and compression that handle H2S. These compressor packages are located next to the well and will treat and compress the gas before being transferred to a pipeline compression facility (mainly utilizing reciprocating compressors) or sour gas removal (sweetening) plant. As gas fields have matured, especially in Canada and the US, and thus leading to drop in field (well) pressures, the screw compressor has become an attractive alternative or supplement to the reciprocating compressor.

The H2S content tends to increase with the reduction in well pressure over time. A compressor facility often needs to be added to a gas well about 3 to 10 years after start of production.

Bearing steel races, especially the highly loaded inner ring raceways, are subjected to H2S attack by stress cracking (SC) and corrosion causing spalling from stress concentrations of inner, and outer rings.

It is known that steel structures in H2S environment, especially in wet condition (consisting of liquid water) is subject to stress corrosion cracking (SSC) in combination with hydrogen embrittlement. SSC is the brittle cracking of a metal due to the result of the combined effects from localized corrosion and stress. Typically stress corrosion cracks have a branched form and a transgranular propagation mode.

Bearing steel races, especially the highly loaded inner ring raceways, are subjected to H2S attacks by stress cracking (SC) and corrosion causing spalling from stress concentrations.

IDEATION

How to Address the Innovation Process

The fundamental ways to approach the innovation process

The ideas first approach:

Most common approach used 90+% of the time because it is fun, easy, exciting and painless . This approach generally does not bring accountability because there are no such things as bad ideas. This means you can have as many ideas as you like (10, 50, 100) that you can document (idea log).

This approach presents a number of problems. How do you know which idea is the best idea. Who in your organization is responsible to evaluate your idea bank? Who is going to evaluate each one to decide which ones should be pursued. This is an impossible task. What criteria would you use to judge the value of these ideas.

The criteria should be the customer needs.

What market is the specific idea targeting and then, what are the needs of those customers in that market and are their needs unmet?

Does the idea address those unmet needs? This concept will likely fail because it is too difficult to pursue which markets and ideas should be address first.

Which ideas are ones that are of true value to your customers.

So let's look at this from a different perspective/approach.

The needs first approach:

First pick a market that you want to pursue so you understand a market you want to be in so any time spent doing ideation in the chosen market is going to be time well spent.

We want to understand the customer needs in that market. How do customers measure successes as they get their jobs done?

Once we have an understanding of those customer needs and which needs are unmet, only then can we have ideas. If there are five unmet customer needs, then there can be a focused five ideas (not 10, 50, 100). You just need 5 ideas to get the job done better.

Next Steps

- Identify 5 unmet customer needs in each business segment.

- Generate 5 ideas with solutions that addresses the unmet needs.

- This brings efficiency to the Ideation process.